KIGEMA applies centrifugal casting to components using all copper and aluminum alloys covered by international and local casting standards (DIN EN 1982:1998-12, PN-EN 1982, DIN 1705, 1709, 1714, PN 91/H-87026, ASTM B271, BS 1400), as well as using special alloys.

Our specialty are large size castings:

Standards: PN-EN 1982, DIN 1705, 1709, 1714, PN 91/H-87026, ASTM B271, BS 1400

Material type: Aluminium Bronze, Tin bronze, Leaded bronze; Brass alloy, Special alloy

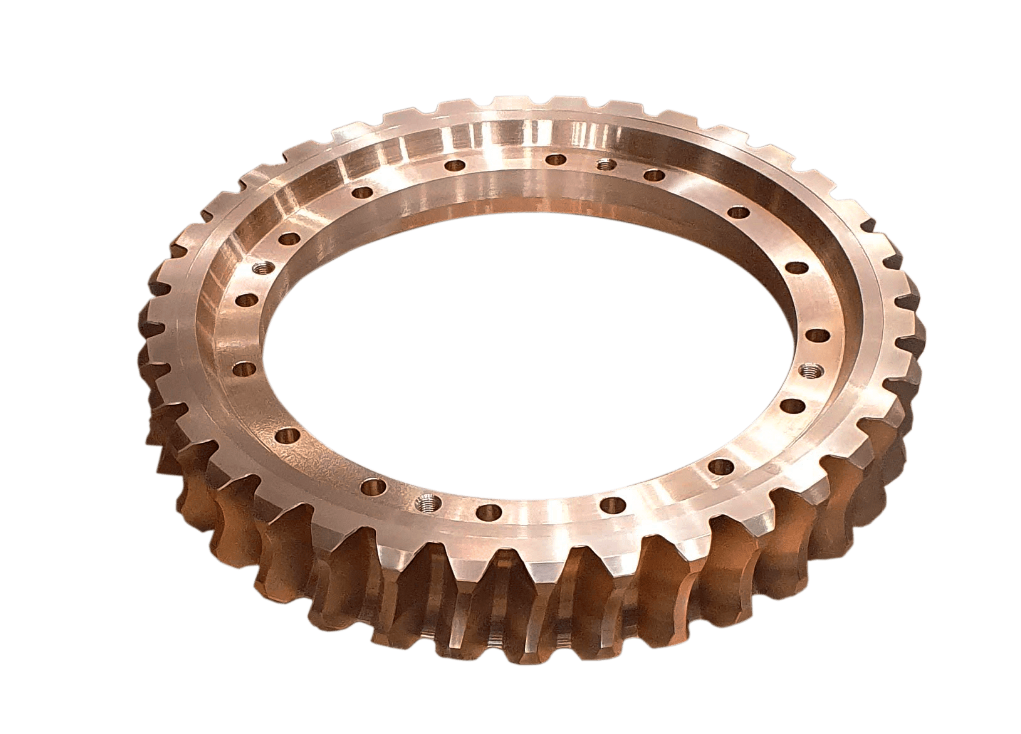

Castings produced by Kigema find their application in large size gearboxes.

Copyrights © 2022 KIGEMA --- Created by Proformat